Typical Uses

The Heavy Duty Swift can be used in all applications that require the use of a yarn swift

Yarn Shops, knitters at home, yarn processors, schools, teachers, and everyone else that needs to use a swift can use our Heavy Duty Swift

Many yarn shops and many knitters at home use an umbrella swift to hold their yarn while they wind their yarn into a ball.

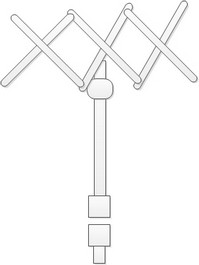

Click to see an umbrella swift

Umbrella swifts

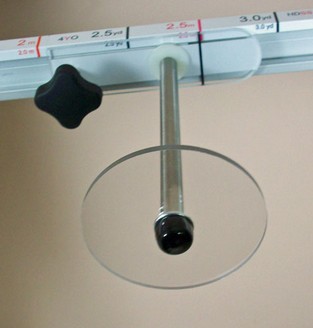

You can see from the picture of our swift on the right, our unit is shaped like a Ferris Wheel. It is vertical and easy to walk up to. Loading and unloading is easy and you do not have to reach over the top like you do on a umbrella swift.

We believe that while umbrella swifts are "neat" tools, they are not heavy duty. They are basically heavy popsicle sticks connected by heavy string. As we said, they are neat tools that play a key role in our industry. However, they do not hold up to the rigors of a yarn shop and they can be awkward to use.

Our vertical orientation is a no-nonsense design. Our aluminum arms are strong yet lightweight. Our yarn guides (old style pictured) have an integrated braking system that allows the user to lock the position of the guide anywhere along the arm's length. They are infinitely adjustable along their 31" length.

The entire unit can be easily rotated as well if you need to target it to some other location in your shop. The table top version can be easily removed from its table stand and inserted into a floor stand in a less than 30 seconds. A motor drive can be added, as well as an electronic rotation counter (ERC). Everything is built around a core product and the user is never asked to abandon part of their system when they upgrade. Literally every other swift/skein-winder on the market is unable to be upgraded.

Our swift and the skein-winder are the same exact product mechanically. We simply put more features and options onto the skein-winder. Without question, our product line is the most flexible and most advanced that is available because of the way we assemble the various options around the core product. This gives our customers tremendous flexibility and expansion capabilities.

Our new guide system is an improved system that is made of steel construction. It is superior to the original wooded guides that were first designed for the system. But just as importantly, they can be reconfigured from 1 to 3 skeins. That is why we named it the Flexi-skeiner™.

How does yarn come from the yarn companies?

Most yarn processors sell their yarn in skeins or hanks. These are large loops of yarn that are made by winding them onto a skein-winder in various circumferences. Typically, these measure 1 to 2 yards in circumference (measured around the entire loop of yarn - not its diameter).

However, knitters need their yarn wound into balls. The mills do not do this for a few reasons. First, they believe that the user can get a better "feel" for the yarn if it is not wound into a ball but rather is left in a skein. Most people feel that the yarn looks better in a skein because you can see the adjacent strands of yarn over a larger, flatter area.

But another important reason is that the mills do not want to take the time to wind the yarn into balls!

This means that the yarn shop will have to wind it into a ball for you or you can do it at home (if you have a ball winder and a swift). It is also possible to wind a ball by hand but this is tedious.

But in all of the cases in which a ball winder is needed to make a ball of yarn, a swift is also needed. So if you need a high quality swift with tremendous flexibility, consider ours. It is a pleasure to use and can handle literally all swift and skein-winder tasks. Plus, it is built to last.

Indie Dyers

These are typically demanding users. After all, their main focus is dying their yarn into specific colors that they have designed or formulated. Their equipment has to be sturdy and reliable. The last thing they want is a failure when they are trying to get their yarn wound, packaged, and sold!

They also need systems that will get the job done for them. That menas they need equipment that is not finicky or fragile and which can handle the loads on a repetitive basis. Lot after lot after lot. They usually cannot afford industrial equipment or they do not have enough work to justify its purchase. Yet they need systems that can electrically wind the yarn and measure its length.

That is where we come in. We can wind their yarn all day long and measure it and do all of this with little user intervention.

We offer them 2 yard and 4 yard units, manual or electric, and meterized. We can also wind up to 3 skeins at a time. We have been told by some indie dyers that winding more than a few skeins at a time is somewhat counterproductive because when the winder stops you must unload the skeins and prepare them (twist and tie them). When only making 2 or 3 at a time, you are back in the action of winding much faster. In tehse cases, they have found it is better to run multiple machine each winding 3 skeins as opposed to having one machine winding 6-10 at one time.

Yarn Shops

Yarn shops are the ones that use swifts the most. Increasingly, they are winding most if not all of their customers' yarn. This means they are winding brand x and then brand y from moment to moment. Not all yarn from the mills is nice, neat, and tidy as it comes off of the skein. Some, I am told, are a disaster.

So yarn shop owners need equipment that is flexible, strong and easy to use. We never want the swift to be the problem, only a reliable helper to help the shop owner "tame" the yarn while they are winding it into a ball (on our ball winder we hope).

Although our unit cannot collapse like an umbrella swift can, it is always in position ready to accept another skein of yarn. The shop owner can lay their skein over the top guide and then easily arrange the rest of the skein around the other three guides. This is much kinder and gentler process than wrestling an umbrella swift.

By the way, our unit does not fly up and almost hit you in the head at the end of a skein like an umbrella swift can.

Our basic 2 yard swift and hold skeins up to 80 inches in circumference (2 meters or 2.2 yards).

Knitters at home

If they can afford our unit and they want the best tool that is available, they should get one of ours. They certainly will do just fine with a quality wooden umbrella swift, and it may be better for them from a space standpoint because the umbrella swift collapses. But they will take special pride in owning one of our commercial swifts or skein-winders for all of the reasons that we cited for the other types of users.